Stainless steel is a strong and useful material, but its price can worry businesses and people. With recent changes in the global stainless steel price, it is vital to find ways to save money. This blog is here to help you cut your stainless steel expenses without sacrificing quality.

Understanding the Price Changes:

Before we

talk about saving money, let us understand what is the stainless steel price trend and why stainless steel prices

change. Problems with the supply chain, higher costs for materials, and more

demand all play a part. Knowing this helps you make smart choices when buying.

Saving Money on Stainless Steel:

· Try Different Options: You might not always need the most

expensive stainless steel. Look into recycled steel or other types that work

just as well but cost less.

· Buy in Bulk: If you often need stainless steel,

try to buy a lot at once. You can ask for discounts from suppliers, especially

if you buy a lot.

· Shop Nearby: It is cheaper to buy from local

suppliers because you save on transportation costs. Plus, it is better for the

environment and your community.

· Look Online: Websites can show you lots of prices

and suppliers. You can compare prices and talk to sellers directly to get a

good deal.

Making Fabrication Easier:

· Use Less: Use costing software to help you cut

stainless steel more efficiently and waste less. Also, try to cut smarter and

use pre-cut pieces when you can.

· Try Machines: Machines like lasers or robots can

help you make things faster and cheaper, especially if you make a lot of stuff.

They might cost more at first but save you money in the long run.

· Train Your Team: If your team knows what they are

doing, they will waste less material. That means you spend less money fixing

mistakes.

Building Good Partnerships:

· Work with Good Suppliers: Find suppliers who are honest and

sell good stainless steel at a good price. Build a good relationship with them

so you can get better deals.

· Be Honest: Tell your suppliers what you need

and how much you can spend. If you're honest, they might give you better prices

or find other ways to help you.

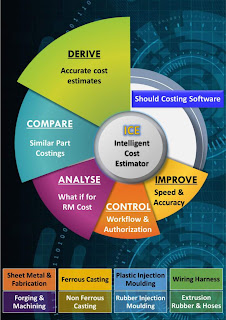

Benefits of Using Raw Material Cost Calculating Software:

When dealing

with raw materials, even small differences can greatly affect your profits.

That is where raw material cost calculating software comes in. It is a helpful

tool that makes processes easier, improves accuracy, and saves money.

· Accuracy Boost: Manual calculations can have

mistakes. Software gets rid of errors, giving precise calculations using

real-time data and formulas.

· Time Saver: Automate calculations to save time

and resources. Quickly analyze different scenarios for better decisions.

· Waste Reduction: Identify where materials are wasted

and how to improve. Optimize cutting and ordering to lower material costs.

· Cost Management: Keep track of costs across projects

and materials. Make better purchasing decisions and negotiate prices with

suppliers using accurate data.

· Profit Boost: By cutting costs and working more

efficiently, the software directly helps increase profits.

Why Choose Cost Masters Software?

· Full Features: Cost Masters has everything you need

for calculating raw material costs, including nesting, yield optimization, and

integration with other systems.

· Industry Know-How: Developed by experts who understand

various industries, the software meets your specific needs.

· Easy to Use: The interface is simple, so everyone

can use it, no matter their technical skills.

· Flexible: Adapt the software to fit your

needs, whether you are a small business or a big company.

· Great Support: Get help whenever you need it from

our dedicated support team.

Here you

read everything about Cost Master’s intelligent cost estimator.

Investing in

Cost Masters software is investing in your business's future. It helps you cut

costs, work more efficiently, and make more money.

.png)

0 Comments